|

The Model T Ford Ignition& its timing

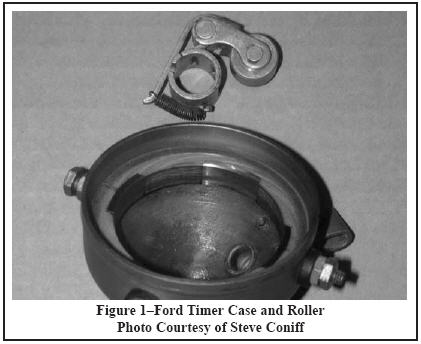

The following is an article on the Model T Ford Ignition System and its timing, written by Ron Patteron & Steve Coniff. For those unfamiliar with the authors, Ron Patterson is a widely accepted expert on the Model T Ford Ignition and often assists enthusiast in trouble with all things ignition. I have been fortunate to receive assistance from Ron on a few occasions and am very gratefull for his assistance with some of the electrical articles on this site. With the possible exception of the planetary transmission, no part of the Model T Ford’s original design is more commonly misunderstood than the magneto ignition system. The purpose of this article is to simply explain how the Model T Ford ignition system and associated spark timing actually work. Figure 1 is an original Ford timer case and roller. This

is important because there were many different manufacturers

of timers other than Ford and they vary significantly in

mechanical design and construction. The Ford timer case

can be usually identified by the word “Ford” in script

stamped into the main case near where the pull lever is

affixed and the roller has similar markings on the spring

loaded roller support arm, see Figure 2. The timer case has

four electrical conductive metal segments mounted in a non-metallic insulator at equally spaced intervals around the

inside circumference of the case. Each conductive segment

has an insulated screw that extends outside the case

perimeter forming a screw terminal with thumbnut where

wiring to the coil box can be connected. The timer roller is

mounted on the end of the camshaft, indexed with a pin and

retained by a locking nut. The roller rides on the inner

surface of the timer case connecting engine ground to each

conductive segment as it rotates thereby completing the

electrical circuit to each coil.

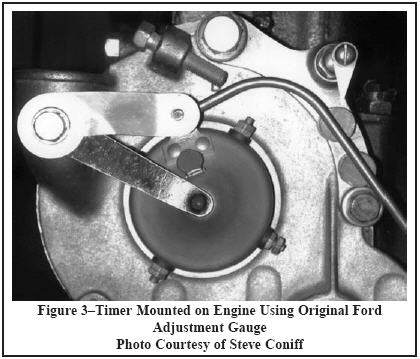

Figure 3 shows the timer mounted on the engine and the

original Ford adjusting gauge used to set the timer at 2.5 inches from the adjacent front plate mounting bolt. With the

spark lever fully retarded (all the way up) the timer pull rod

is appropriately bent to insert the end of the rod into the

timer lever hole without changing the 2.5-inch

measurement. As the steering column spark lever is moved

through its quadrant, which consists of 28 notches, the timer

case moves through its range of movement advancing the

spark at a rate of approximately 2.85 crankshaft degrees per

notch. This relationship is not exactly linear because of the

angle of the pull lever on the end of the spark rod.

For the purposes of this discussion it is important to

understand the basic electrical characteristics of the

magneto output. The magneto output is an AC signal of

varying voltage, frequency and current with eight complete cycles for each crankshaft revolution. The voltage varies

over the normal range of engine speed from a low of 4 volts

to a high of over 30 volts with sufficient current capacity to

operate the coil. The sixteen positive and negative peaks of

this signal are separated by 22.5 degrees of crankshaft

revolution. The significance of this last point will be

explained later.

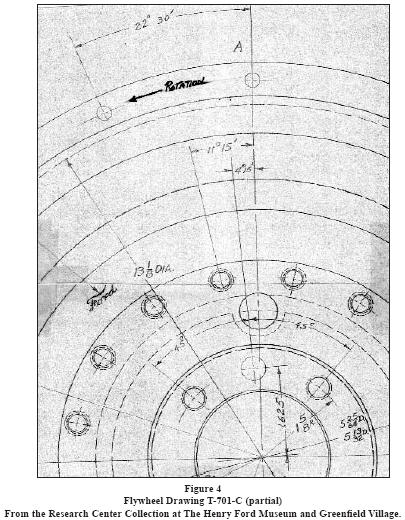

Figure 4 shows a portion of Model T flywheel drawing

T-701-C (viewed from the transmission side). If you study

this drawing carefully you will see the magnets are mounted

on the flywheel in such a way that the magneto output is

advanced from Top Dead Center (TDC) by 7 degrees of

crankshaft rotation. (11 Degrees 15 Seconds minus 4

Degrees 15 Seconds equals 7 Degrees) The significance of

the magnet mounting will be explained later. The Record of

Changes for the flywheel drawings indicate the magnet

mounting was unchanged for all Model T production.

The construction of the Model T ignition coil is well

understood and will not be described in further detail here.

For the purposes of this discussion it is important to understand that proper

operation of the coil points will affect ignition timing and

hence engine performance. Additionally, the ignition coil

operates entirely different when running on battery as

opposed to magneto. When a properly adjusted ignition coil

is running on battery and the roller grounds the timer

segment, the coil will vibrate continuously and provide

voltage to fire the spark plug. When a properly adjusted

ignition coil is running on magneto and the roller grounds

the timer segment the coil points respond to the individual

current pulses of the magneto output to fire the spark plug.

To reliably and consistently respond to the individual

magneto current pulses and maintain accurate ignition

timing the coil points must be carefully adjusted. The only

way correct point adjustment can be attained is by using a

hand cranked coil tester which simulates conditions very

similar to that which occur in the Model T ignition system

when running on magneto.

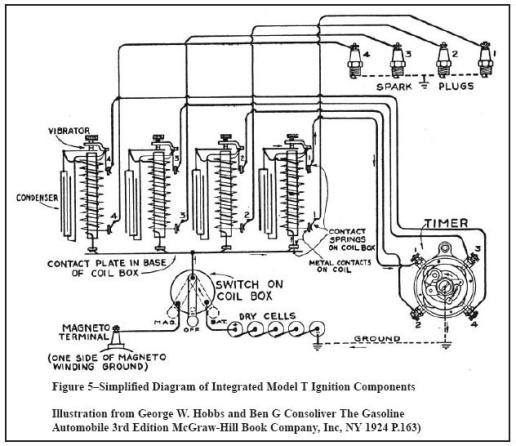

Figure 5 is a simplified diagram of all the various

ignition components integrated together as a system.

Now lets discuss the detailed spark timing measurements

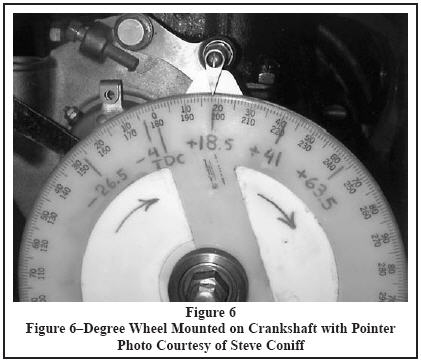

we took. Figure 6 depicts the method used to take the annular

degree measurements. Remember, wherever the word

“degree or degrees” is used hereinafter it is understood to

mean “crankshaft degrees of rotation”. A degree wheel was

mounted on the end of the crankshaft with a stationary

marker pointing to the scale. TDC was located on cylinder

one, the degree wheel indexed so the marker pointed to “0”

degrees and fixed so the inter-relationship would not change

as the crankshaft was rotated.

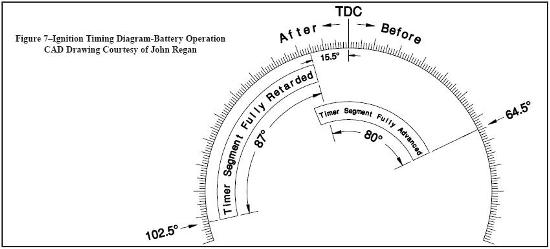

Figure 7 is a diagram depicting the first set of measurements.

The engine front plate was checked for concentricity

with the end of the camshaft. A reground Ford camshaft,

good original Ford timer case and NOS timer roller were

used to take these readings. The timer case was positioned

using the Ford gauge. By manually rotating the crankshaft it

was determined that the timer segment was grounded at 15.5

degrees after TDC and remained grounded for 87 degrees.

As the timer case was moved through its range of the spark

lever quadrant it was found the total advance of the timer

case was 80 degrees.

As previously mentioned, when operating on battery,

the ignition coil will vibrate continuously firing the plug as

long as the timer segment is grounded. As you can see in

Figure 7 the coil will continuously fire the spark plug

starting at 15.5 degrees after TDC and cease at 102.5

degrees after TDC. As engine speed is increased and the spark lever advanced the coil will fire the spark plug throughout the degree range of the timer case movement until it reaches maximum advance of 64.5 degrees before TDC.

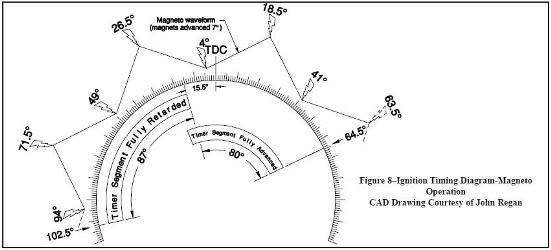

Figure 8 is a diagram depicting the second set of measurements.

The test set up is unchanged and the intervals of

timer segment and timer case movement are the same.

When taking these measurements a properly rebuilt Model

T coil was electrically connected to the timer, magneto and

spark plug and the engine rotated at 600 RPM. An

automotive ignition timing light was connected to the spark

output to read the position of the degree wheel pointer to

determine exactly where the coil fires in relationship to

crankshaft position.

The magneto waveform depicted in Figure 8 is representative

only and does not reflect the shape of the magneto

waveform when viewed on an oscilloscope. But it does reflect the timing relationship attained by advancing the

magnets on the flywheel by 7 degrees as indicated on

flywheel drawing T-701-C. The spark symbols show the

points where the ignition coil will fire on the magneto

current output with respect to piston travel. Each of these

locations is logically separated by 22.5 degrees.

When starting the Model T engine on the magneto with

the spark lever fully retarded, the coil initially fires at 26.5

degrees after TDC. This is the nearest location based upon

the timer case (spark lever) position where sufficient

magneto current output is available. As engine speed is

increased and the spark lever advanced the coil will initially

fire at one of the additional locations where sufficient

magneto current output occurs. These locations are 4

degrees after TDC, 18.5 degrees before TDC, 41 degrees

before TDC and possibly 63.5 degrees before TDC. The

spark depicted at 63.5 degrees before TDC spark may not

occur depending upon the travel of the spark lever past the

end of the quadrant.

Figure 8 helps explain why it is easier to start a Model

T on magneto when the spark lever is advanced a few

notches. By advancing the spark lever the coil will fire at 4

degrees after TDC. If the magnets were not advanced 7

degrees the coil would initially fire at 11.25 degrees after

TDC.

Figure 8 also helps explain why the engine sometimes

speeds up when switching from battery to magneto. There

are locations of spark lever setting when running on battery

that will result in more optimal spark timing when switched

to magneto.As you can see in Figure 7, when running on battery,

linear spark timing can be obtained by moving the spark

lever. This would appear best for optimum engine

performance, but Model T coils do not work well on the 6

volt battery at higher engine speeds.

As you can see in Figure 8, when running on the

magneto, timing advance is not linear. The spark lever is a

selector that, when moved, determines the magneto current

pulse where the ignition coil will supply spark voltage to the

plug.

Get this articleIf you'd like a pdf copy of the original of this article, click below

|